Drying Rooms – What Are They For and What Are The Benefits?

The purpose of a drying room is to create and maintain the ideal temperature and humidity. When using a drying room, the product should be dried or cured rapidly while still maintaining or improving its quality.

DRYING ROOMS FOR FOOD AND MEAT

If a drying room is used to age dry meat, a continued balance between water evaporation on the meat’s surface and extraction of water from the deeper layers is required.

“This is the best set up I’ve seen. It has improved the quality and taste of the meat and increased our yield to market as less meat needs to be trimmed during the aging process.”

It is a fine balance between the surface area of the meat not becoming too dry while maintaining a high moisture content inside the meat. Dry surfaces hinder further evaporation of moisture which leads to the meat not drying evenly and can cause spoilage.

DRYING ROOMS FOR ORGANIC MATERIAL

When drying organic material, there is a variety of potential issues when the room’s temperature and humidity is not properly maintained. For example, when drying timber, you want the room to remain warm, however fluctuating temperature and humidity can make the timber warp. To ensure the timber remains in its optimal state, the room needs to remain warm but dry.

Humiscope has several clients drying products in their commercial drying room from cannabis to flower drying. One client that dries flowers in order to extract the essence for a cosmetic manufacturer used to send the flowers wet to a freeze dry company who then sent it to the international cosmetic manufacturer.

The time between sending the wet flowers and it being freeze dried by a third party before sending it overseas, led to a loss in quality and a reduction in the amount of essence that could be extracted.

Using a desiccant dehumidifier in a properly sealed and ducted drying room removed the need for the middleman and increased both the quality of the product and the amount of vital ingredient that was to be extracted.

“The dehumidifier is working very well with the weight of the product dropping – which was the goal. The space was loaded with 50 kg of product yesterday and this morning it weighs only 36.5 kg.’

Bacteria and Mould

In addition to preserving the structural integrity of products, a drying room also helps prevent the growth of mould and bacteria.

These microorganisms thrive in moist environments, and if they grow on products such cannabis it leads to rot, botrytis and downy mildew – severely reducing the viability of the product.

In regard to drying food products, if the room’s indoor environment is not properly maintained and the area becomes damp or humid, it creates an ideal breeding ground for bacteria and other microorganisms - causing food to spoil, rendering it unsafe to eat.

ISSUES WITH COMMERCIAL DRYING ROOMS

Meat Drying Rooms

A commercial drying room for meat is designed to create a climate-controlled environment where moisture can be extracted from the product being dried.

The room should remain, as the name implies, dry. However, it is storing meat, so the room also has to remain very cold – below 4° C. This dual requirement provides challenges in combating the moisture created by refrigeration units.

Organic Materials Drying Room

The indoor temperature and humidity of drying rooms should be consistent with little fluctuation in temperature and humidity.

Heating is an oft used application, however the air has to be heated more than the ambient air temperature which means that the heating device will have to run at different temperatures during different seasons. This is costly and increases energy consumption.

WHAT IS THE SOLUTION?

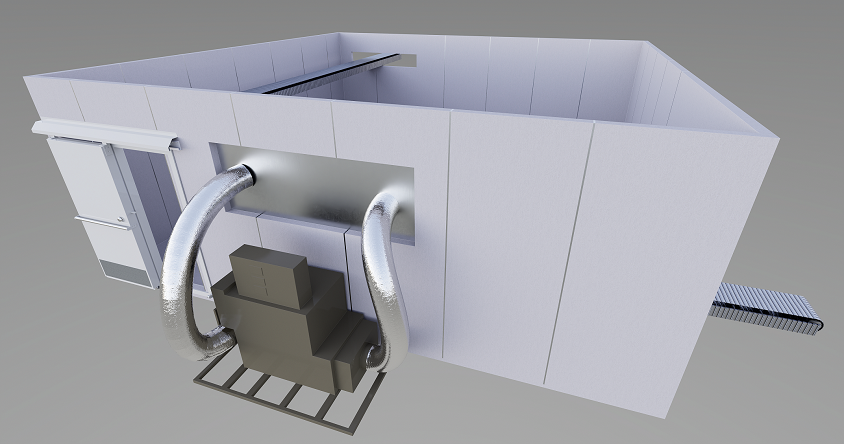

Dehumidification technology in a properly sealed and ducted room.

Dehumidifiers remove moisture from the air and create a dry environment. Dehumidification increases refrigeration efficiency and equipment and system reliability which in turn reduces operating costs and lowers energy consumption.

Drying rooms with specifically designed dehumidification systems professionally installed, provides complete and optimal indoor climate control for hygroscopic and moisture sensitive material.

Humiscope custom design and build drying rooms complete with superior quality HVAC+R systems (heating, ventilation, air-conditioning and refrigeration), with a special focus on dehumidification. We also convert existing spaces into fully sealed and ducted drying rooms.

Please visit our website to read more about drying rooms and desiccant dehumidification technology. Also check out our Commercial Drying Room case studies and see what our clients are saying.